Techincal Note 4.0

Composition & Thermal Tempering of MadHatter™ 2 -Piece Iron Rotors

Like most aspects of rotor technology, there are trade-offs to be weighed in the quest for maximum mechanical strength, maximum thermal stability under extreme stress and superior wear characteristics, while at the same timer, minimizing weight and production costs.

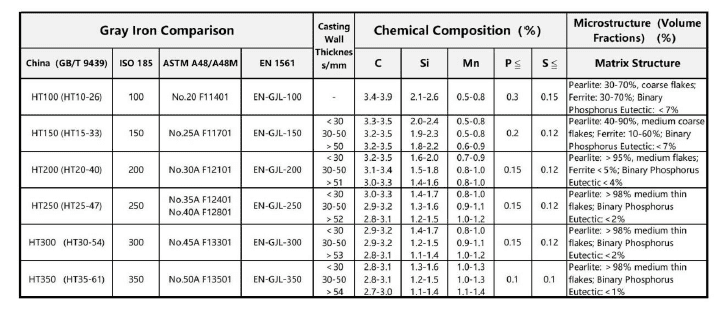

As noted in Table 1, Performance Brake Systems (PBS) uses a low-C, low-Si, high-Mn grade alloy of grey iron for the iron rotor rings, known internationally as HT250 (ISO 185-250) combined with a proprietary 3-step thermal tempering process.

This is different than the common use of HT150 & HT200 grey iron with little or no tempering, used in rotor manufacturing. HT150/200 have a higher coefficient of friction, but are also less durable in terms of wear and deformation. PBS believes that a tempered HT250 offers the best balance of good performance with superior longevity under harsh conditions.

The carbon content of our HT250 is at or below 3.0%. The resultant Pearlite distribution (graphite flakes) is a >98% uniform medium thin flake distribution, resulting in superior strength characteristics as noted in Table 2.

3-Step Thermal Tempering

The use of HT250 grey iron however, requires the careful use of thermal tempering (a 2-day process) to ensure the reduction of brittleness commonly associated with HT250.

Post casting, the rotors are thoroughly cleaned of all contaminants and chemically treated with an annealing agent. The rotors are then heated very gradually under strict gradient control to 800C and kept there for several hours. The rotors are then cooled in a carefully controlled reverse gradient. This process is repeated three (3) more times and under different, proprietary gradients of heating and cooling.

This lengthy tempering process results in a highly stabilized metallic grain structure, ensuring maximum thermal stability and greatly improved metal fatigue under repeated high-heat cycles.

Through innovation, expertise, and dedication to customer satisfaction, PBS is revolutionizing the high-performance braking industry, one rotor at a time.

GET IN TOUCH

For more information or to find the right 2-piece floating iron rotors for your vehicle, contact our team of experts. We’re here to help you make the best choice for your braking needs.